llama a :

+86 18681515767

llama a :

+86 18681515767

correo electrónico :

marketing@jtspeedwork.com

correo electrónico :

marketing@jtspeedwork.com

llama a :

+86 18681515767

llama a :

+86 18681515767

correo electrónico :

marketing@jtspeedwork.com

correo electrónico :

marketing@jtspeedwork.com

01. nuestros productos

Productostecnología co de shenzhen jietong., ltd. es una empresa de alta tecnología que se dedica al desarrollo, producción y venta de identificación por radiofrecuencia (rfid).

siempre un paso más!

Shenzhen Jietong Technology Co., Ltd es una empresa de alta tecnología centrada en I+D, producción y venta de hardware UHF RFID. Jietong tiene su propio equipo de I + D, cuyos ingenieros tienen más de 10 años de experiencia en I + D. Con el fin de brindar el mejor servicio y producto al cliente, Jietong se encuentra en continuo desarrollo para ofrecer una solución completa para el proyecto, servicio posventa y soporte tecnológico. Jietong tiene líneas de productos principales que incluyen lector de lectura de etiquetas múltiples UHF RFID Impinj R2000/TM200 , lector de lectura de etiqueta única UHF RFID , lector de largo alcance UHF RFID , lector de medio alcance UHF RFID , lector/escritor de escritorio UHF RFID , módulo de lector UHF RFID , Lector de mano UHF RFID , Antena UHF RFID , Tarjeta y etiqueta UHF RFID , etc., Jietong tiene el principio de la supremacía de los usuarios, y depende de la nueva tecnología orientada al mercado y de alta calidad, proporcionaremos la última tecnología, los mejores productos, la competitividad, el servicio sincero a nuestros clientes. Nos hemos consolidado como una parte confiable, innovadora y confiable de los negocios de sus clientes y proveedores.

02. Por qué elegirnos

nuestra ventajatecnología co de shenzhen jietong. ltd., es una empresa de alta tecnología enfocada en i + d, producción y venta de identificación por radiofrecuencia (rfid). lector de serie profesional especial en rfid uhf de internet de las cosas. jietong tiene su propio equipo de I + D, cuyos ingenieros tienen más de 10 años de experiencia en I + D. Con el fin de brindar el mejor servicio y producto al cliente, jietong está en continuo desarrollo para ofrecer una solución completa para el proyecto, servicio postventa y soporte tecnológico.jietong tiene líneas de productos principales que incluyen módulo rfid uhf, lector de mano rfid, lector rfid uhf, lector rfid de rango medio para estacionamiento de automóviles, lector de control de acceso uhf, antena uhf, tarjetas y etiquetas uhf, etc.El lector jt uhf rfid ya se utiliza en la gestión de vehículos de forma intensiva, el uso del entorno también incluye la gestión de personal para la fábrica, la gestión de peso para el almacén, el control de acceso para el almacén y el vehículo, la gestión de la ropa, la gestión de la logística del tabaco, la gestión inteligente de la biblioteca, la gestión de la identificación de la línea de producción, los activos gestión, etc.,jietong tiene el principio de la supremacía de los usuarios, y depende de la nueva tecnología orientada al mercado y de alta calidad, proporcionaremos la última tecnología, los mejores productos, el competitivo, el servicio sincero a nuestros clientes.

profesional

profesional

el equipo de I + D + i cuenta con más de 10 años de experiencia;

producto

producto

ofrecer productos de bajo costo, calidad media y alta;

calidad

calidad

protección de patente nacional para productos de marca propia

Servicio

Servicio

2 años de garantía y 3 años de coste de mantenimiento;

03. casos de proyectos

SOLUCIÓN Y CASOEsta página de soluciones ayuda a los clientes a resolver el problema de instalar y administrar aplicaciones utilizando los productos de Jietong Technology. Se incluyen los siguientes: Gestión de vehículos Gestión del sistema personal UHF Gestión de la línea de producción Gestion de logistica Gestión de activos Gestion de almacenes Gestión de vehículos de saneamiento ambiental Gestión inteligente de librerías

RFID Technology in the Renewable Energy Sector: Applications and Opportunities 1. Introduction As the global renewable energy industry expands, efficient asset management, supply c...

Lee mas

gestión de vehículosCon el rápido desarrollo de la economía china, el nivel de vida de las personas está aumentando y la propiedad total del automóvil también comenzó a crecer rápi...

Lee mas

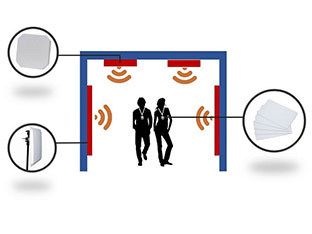

uhf rfid sistema de gestión de personal>> descripción general del sistemaEl sistema de gestión de personal de tarjetas de larga distancia es el sistema moderno de gestión de person...

Lee mas

gestión de la línea de producciónPara producir productos de mejor calidad, mientras se reducen los costos de producción y se cumplen los requisitos de iso9000, los fabricantes sigu...

Lee mas

gestión de guiado de carriles de carro agvCon el nivel de fabricación y la creciente demanda de los clientes, una variedad de sistemas logísticos se enfrentan a muchos desafíos, co...

Lee mas

sistema de gestión de activos rfidResumen del sistemaLa forma de implementar manualmente la gestión de activos, incluido el aumento de activos, la distribución, el almacenamiento, ...

Lee mas

04. eventos

últimas noticiastecnología co de shenzhen jietong., ltd. es una empresa de alta tecnología que se dedica al desarrollo, producción y venta de identificación por radiofrecuencia (rfid).

05. consulta gratis

deja un mensajeSi está interesado en nuestros productos y desea conocer más detalles, deje un mensaje aquí, le responderemos lo antes posible.

teléfono : +86 18681515767

Whatsapp : +8618681515767

correo electrónico : marketing@jtspeedwork.com

12/F, Building A, No. 6, Shiben Road, Shiyan Street, Bao'an District, Shenzhen, Guangdong, China-518108

derechos de autor © 2026 Shenzhen Jietong Technology Co.,Ltd. todos los derechos reservados.

compatible con la red ipv6