llama a :

+86 18681515767

llama a :

+86 18681515767

correo electrónico :

marketing@jtspeedwork.com

correo electrónico :

marketing@jtspeedwork.com

llama a :

+86 18681515767

llama a :

+86 18681515767

correo electrónico :

marketing@jtspeedwork.com

correo electrónico :

marketing@jtspeedwork.com

Smarter, Safer, Traceable: How RFID Reinvents EV Battery Management

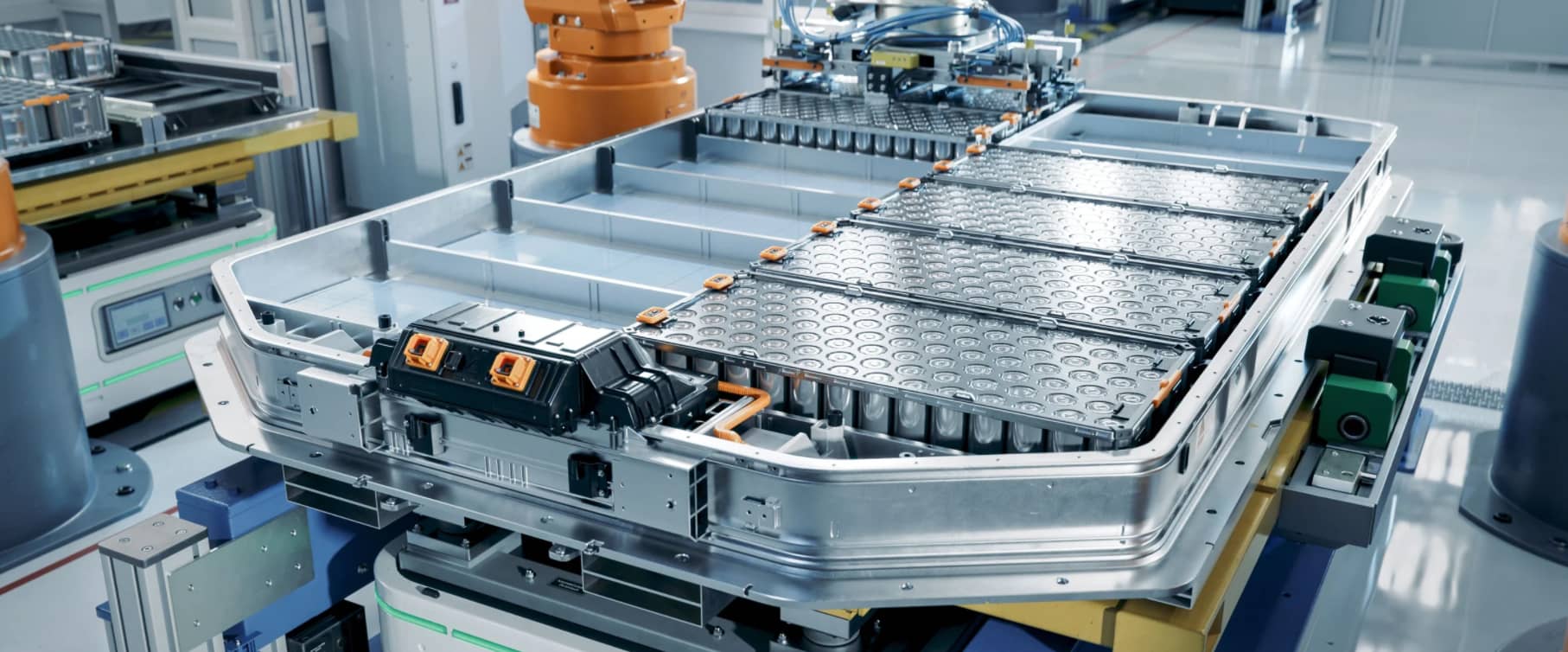

As electric vehicles continue to expand their share of the global market, the role of the power battery has become more central than ever. Performance, safety, and lifecycle transparency all hinge on how well each battery is tracked and managed. Traditional approaches—manual recording, printed barcodes, or relying solely on on-board BMS data—are increasingly stretched as production scales and cross-regional circulation intensifies. In this context, RFID has emerged as a practical tool, offering non-contact identification, stable long-distance reading, and strong resistance to dust, vibration, and harsh environments.

At the core of applying RFID to battery management is the idea of giving each battery a digital identity. An RFID tag attached to a cell, module, or pack acts as a unique identifier. It holds essential information throughout the battery’s lifecycle, forming a reliable foundation for monitoring, maintenance, and regulatory oversight.

In manufacturing, where dozens of processes—from material mixing and cell formation to module assembly and pack testing—must be tightly coordinated, RFID simplifies data collection and verification. Test results such as initial voltage, internal resistance, temperature performance, and aging data can be written directly into the tag and synchronized with backend systems. Instead of cross-checking multiple databases or manual logs, engineers can scan the battery at any point on the production line and instantly confirm whether it meets required specifications. This cuts down on errors and improves overall production efficiency.

Once the battery reaches vehicle assembly and after-sales service, RFID provides another layer of convenience. Unlike barcodes, which need close-range scanning and can be easily damaged, RFID works even when the battery is installed beneath the vehicle floor. Service technicians can quickly retrieve the battery’s history—charging cycles, past temperature anomalies, or repair records—without dismantling the pack. This makes troubleshooting more accurate and helps manufacturers identify abnormal patterns across different batches.

Safety remains one of the most critical concerns in the EV industry. While the BMS monitors voltage, temperature, and current during vehicle operation, its coverage does not extend to storage, logistics, secondary use, or recycling. RFID fills this gap by ensuring that each battery can be identified and traced even outside the vehicle. If an overheating incident or abnormal swelling is found during transport or warehouse inspection, the battery’s origin and distribution path can be traced immediately. This allows companies to isolate risks quickly and conduct precise recalls when necessary.

As batteries reach the end of their automotive life, RFID becomes even more valuable in the recycling and repurposing stages. Decisions about whether a retired battery is suitable for energy-storage applications depend heavily on accurate historical data. Cycle count, State of Health, peak temperature records—information stored in the RFID tag—helps recycling companies classify batteries and determine appropriate reuse scenarios. When dozens or hundreds of second-life batteries are grouped for storage projects, RFID also enables quick sorting and risk management.

In logistics, the transportation of lithium batteries requires compliance with strict safety rules. RFID placed on battery trays or containers helps track route progress, dwell times, and environmental conditions. Scan records from each logistics checkpoint form a complete traceability chain, offering both companies and regulators clearer visibility into the transport process.

From an industry-wide perspective, RFID contributes to building a transparent lifecycle management system. Regulatory agencies increasingly require clear records of battery production, circulation, repurposing, and disposal. RFID makes this process more reliable by offering consistent identity authentication across different platforms and regions, and by reducing the workload associated with manual input or barcode updates.

Deploying RFID in battery systems does present challenges. The metal-rich structure of battery packs can interfere with radio signals, so specialized anti-metal tags or ceramic antennas are often required. Batteries also endure high temperatures and mechanical stress, meaning the tags must be durable and securely encapsulated. Integrating RFID data with BMS, MES, logistics, and service platforms requires unified standards and stable interfaces—an area still evolving across the industry.

Despite these challenges, the overall direction is clear. RFID is becoming a foundational element of intelligent battery management. As EV adoption rises and battery value continues to grow, transparent, reliable lifecycle data will be essential for manufacturers, users, and regulators alike. With RFID enabling precise identification and traceability, each battery can be monitored, evaluated, and handled with greater confidence.

In the long run, RFID strengthens the entire EV ecosystem. It supports safer vehicles, more efficient maintenance, clearer regulatory compliance, and more responsible recycling practices. As costs decrease and industry standards mature, RFID will continue to play an increasingly important role in shaping the future of battery management.

categorias

nuevo blog

derechos de autor © 2026 Shenzhen Jietong Technology Co.,Ltd. todos los derechos reservados.

compatible con la red ipv6